Over 10,000+ customers' choice, Focus on screening industry 40+ years

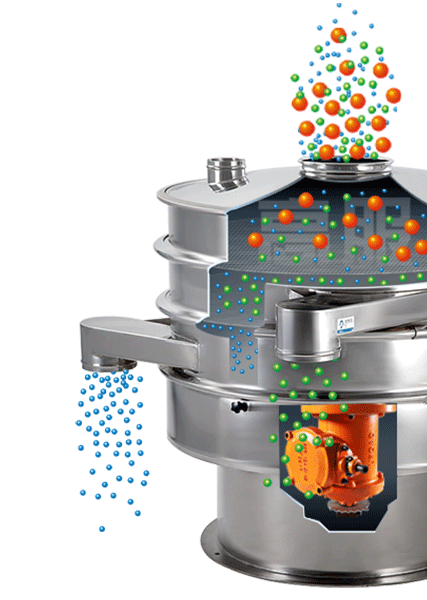

Our rotary vibrating screen uses a vertical vibrating motor as the excitation source. The upper and lower ends of the vibrating motor are equipped with eccentric weights, which convert the rotating motion of the vibrating motor into horizontal, vertical, and tilted three-dimensional movements. This movement is transmitted to the screen surface.

Can sieve any powder down to 600 mesh(0.02mm), and filter mucus up to 5 microns.

1 to 5 layers of sieves can be used to sort two to six particle size at the same time.

For different materials’ screening requirement, matching different screen frame form.

Impurities and coarse materials are automatically discharged, and continuous operation is possible.

Replacement completed in 3-5 minutes.

The rotary vibrating screen is highly maneuverable due to the castor wheels which reduces the number of hands required for its operation.