SCREENING

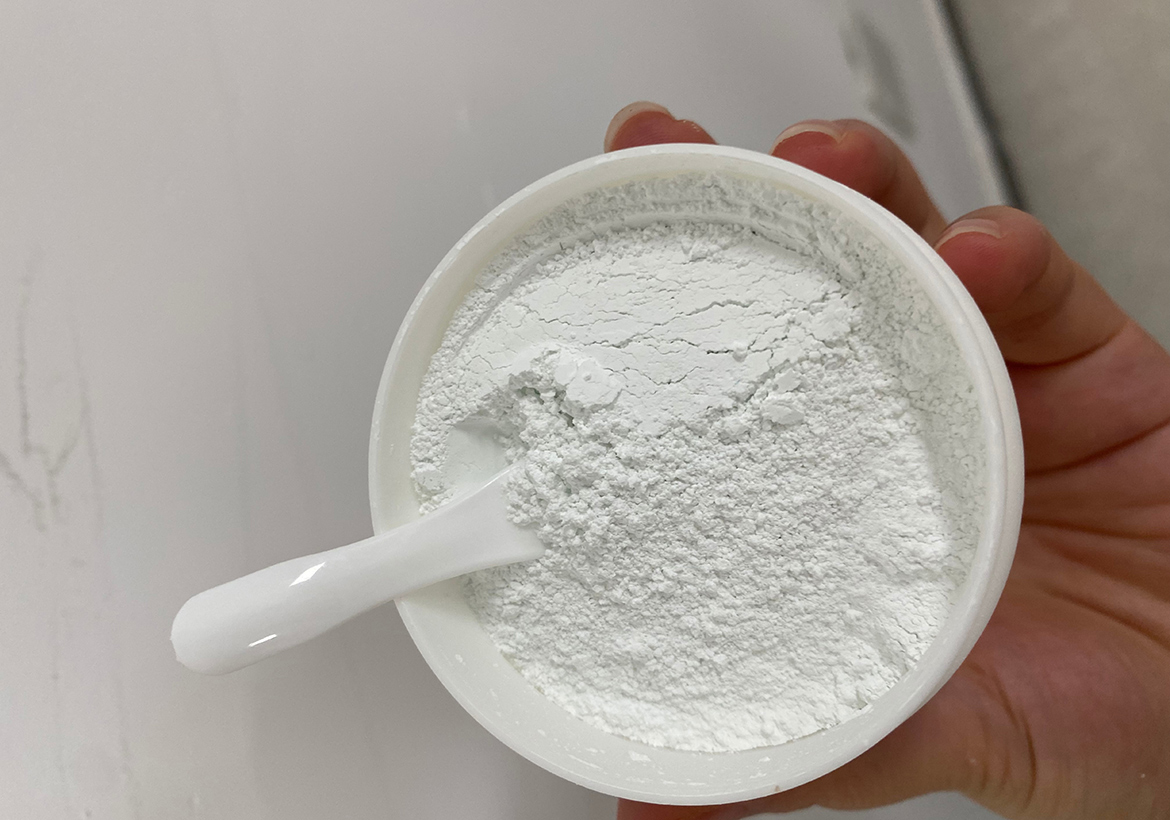

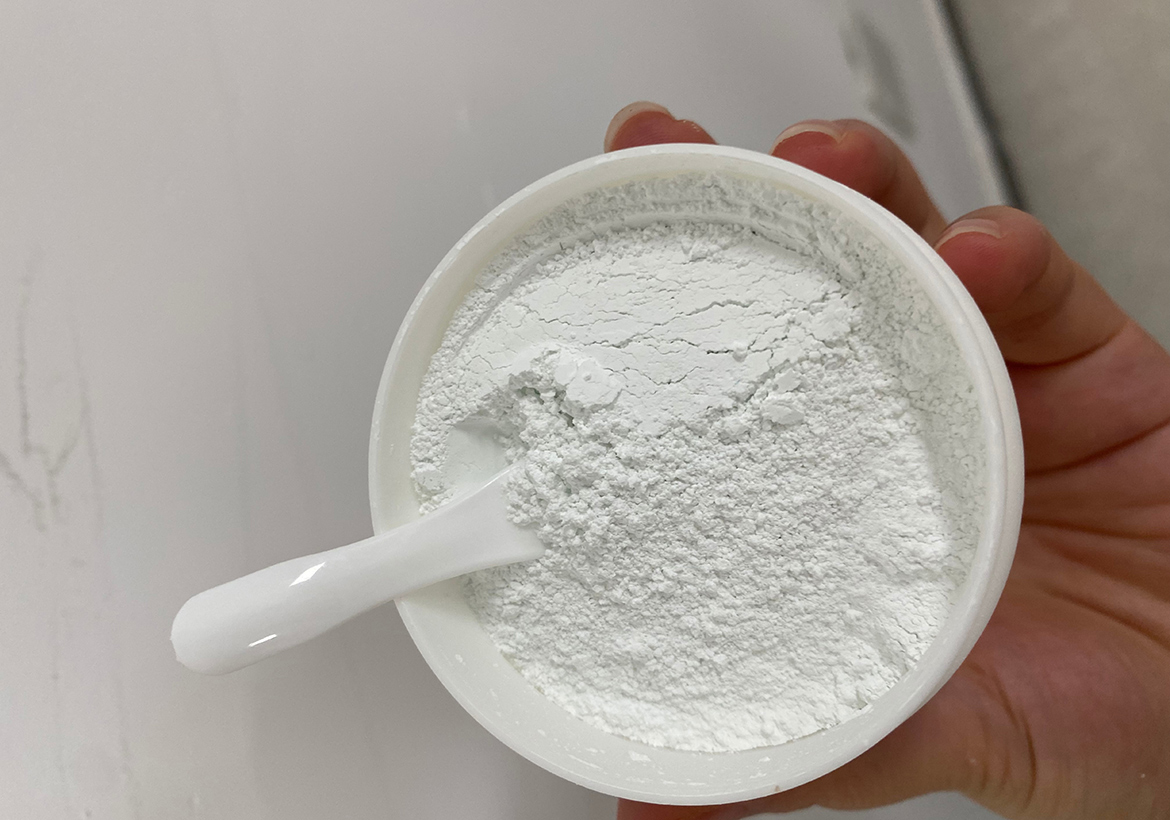

Tooth Powder

Over 10,000+ customers' choice, Focus on screening industry 40+ years

As a product that comes into direct contact with the oral cavity, tooth powders have much higher requirements for safety, uniformity, and fineness than ordinary powders. A vibrating screen not only ensures product safety and user experience but also supports the stability and compliance of the production process. Without a vibrating screen, tooth powders are prone to problems such as tooth damage, uneven efficacy, packaging problems, and compliance risks, failing to meet both market and regulatory requirements.

1. Raw material removal: Eliminate safety hazards and ensure oral safety.

2. Particle size control: Ensure frictional compatibility and optimize the brushing experience.

3. Mixing aid: Break down raw material clumps and ensure uniformity.

4. Finished product refining: Enhance appearance and flowability to meet packaging and storage requirements.

5. Compliant production: Meet industry standards and mitigate quality risks.

Coarse Material Screening

Recommended Model: Linear Vibrating Screen

Screening Mesh: 40-100 Mesh

Processing Capacity: 500-2000 kg/h

Fine Powder Screening

Recommended Model: Rotary Vibrating Sieve, Ultrasonic Vibrating Sifter

Screening Mesh: 120-300 Mesh

Processing Capacity: 300-1000 kg/h